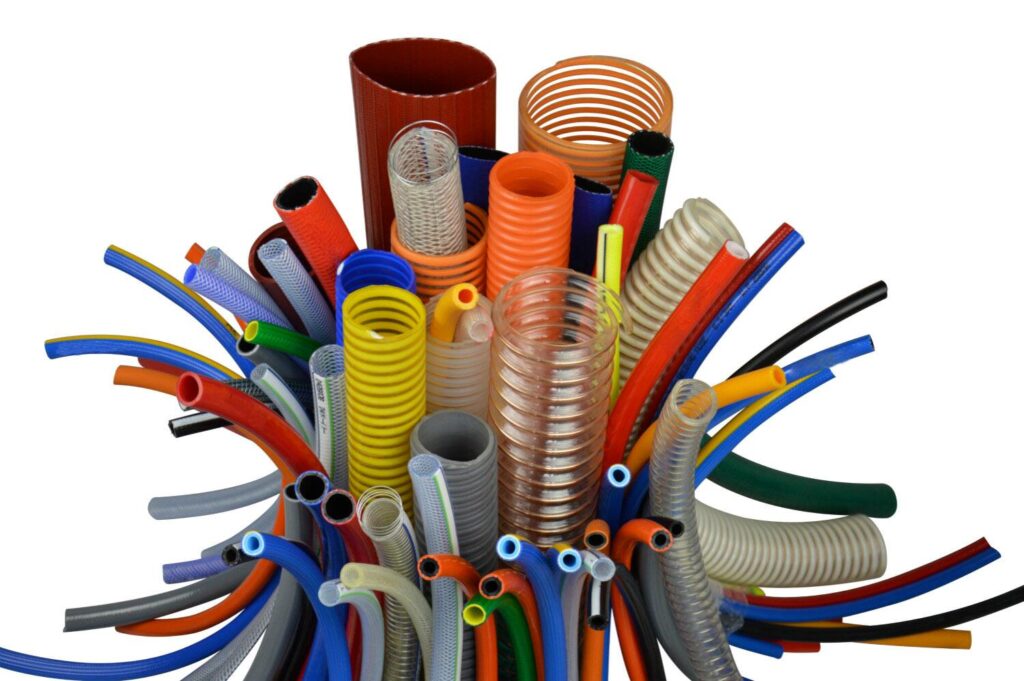

Selecting the right PVC HOSE Manufacturer for your application is crucial for ensuring efficient operation, safety, and longevity. With various types of hoses available on the market, understanding their specifications can be overwhelming. This article aims to demystify PVC hose specifications by breaking down the key factors to consider when choosing the right hose for your needs.

1. Hose Diameter

Importance of Diameter:

- The diameter of a PVC hose affects its flow capacity and pressure rating. Selecting the correct diameter ensures optimal fluid transport, reducing the risk of blockages and pressure loss.

Standard Sizes:

- PVC hoses typically come in various standard diameters, such as ½ inch, ¾ inch, 1 inch, and larger. The choice of diameter should be based on the specific requirements of your application.

2. Pressure Rating

Understanding Pressure Ratings:

- The pressure rating indicates the maximum pressure that the hose can withstand without failure. It is typically measured in pounds per square inch (PSI).

Choosing the Right Rating:

- When selecting a hose, consider the pressure requirements of your application. Always choose a hose with a pressure rating higher than the maximum pressure it will experience during use. This safety margin helps prevent hose failure and enhances longevity.

3. Temperature Tolerance

Temperature Range:

- PVC hoses have specific temperature tolerances, which are crucial for applications involving hot or cold fluids. Understanding the temperature range helps prevent hose degradation and ensures optimal performance.

Selecting Based on Conditions:

- Check the manufacturer’s specifications for the temperature limits of the PVC hose. Most PVC hoses can handle temperatures up to 140°F (60°C), but some specialized hoses can tolerate higher temperatures. Be sure to choose a hose suitable for your operating conditions.

4. Chemical Compatibility

Assessing Chemical Resistance:

- PVC hoses are known for their resistance to various chemicals, but not all hoses are suitable for every chemical. Understanding the chemical compatibility of the hose material is essential for preventing degradation or failure.

Consulting Compatibility Charts:

- Most manufacturers provide compatibility charts that outline the resistance of their hoses to specific chemicals. When selecting a hose, refer to these charts to ensure it will perform well with the fluids it will carry.

5. Reinforcement and Construction

Types of Reinforcement:

- Some PVC hoses come with reinforcement, such as braiding or helical wires, to enhance strength and pressure resistance. Reinforced hoses are ideal for high-pressure applications or environments where the hose may be subject to external stresses.

Construction Types:

- PVC hoses can be constructed using various methods, including single-layer or multi-layer designs. Multi-layer hoses can offer improved flexibility, durability, and chemical resistance.

6. Flexibility and Handling

Evaluating Flexibility:

- The flexibility of a PVC hose is important for ease of installation and maneuverability in tight spaces. Some applications may require more flexible hoses, while others may prioritize stiffness for structural integrity.

Considering Handling Requirements:

- Assess how the hose will be used and handled during operation. If frequent movement or bending is required, choose a hose known for its flexibility without compromising strength.

7. Length and Coil Size

Standard Lengths:

- PVC hoses are available in various lengths, often ranging from 25 feet to 100 feet or more. Selecting the appropriate length is essential to ensure sufficient reach without excess hose, which can lead to tangling or reduced efficiency.

Coil Size:

- If you require a longer hose, consider the coil size for storage and transport. Some hoses may come coiled, while others are available in straight lengths.

8. Safety Standards and Certifications

Importance of Compliance:

- Ensure that the PVC hose meets relevant safety standards and certifications, especially for applications involving food, pharmaceuticals, or chemicals. Compliance with standards such as FDA, NSF, or RoHS enhances trust in the product’s safety and reliability.

Manufacturer Reputation:

- Research the manufacturer’s reputation regarding quality and compliance. A reputable manufacturer is more likely to provide hoses that meet or exceed industry standards.

9. Cost Considerations

Budgeting for Quality:

- While it may be tempting to opt for the cheapest option, remember that quality often correlates with price. Investing in a higher-quality hose can result in better performance, longevity, and fewer maintenance issues in the long run.

Total Cost of Ownership:

- Consider the total cost of ownership, including maintenance and replacement costs, when evaluating your options. A higher upfront cost may be justified by reduced downtime and increased efficiency.

Conclusion: Making Informed Decisions

Understanding PVC HOSE Manufacturer specifications is essential for making informed decisions that enhance operational efficiency and safety. By considering factors such as hose diameter, pressure rating, temperature tolerance, and chemical compatibility, you can select the right PVC hose for your specific application.

Taking the time to evaluate these specifications will not only ensure optimal performance but also contribute to the longevity and reliability of your fluid transport systems. With the right PVC hose in hand, you can confidently tackle your industrial challenges and ensure smooth operations for years to come.